In the dynamic field of defense and security, ballistic shields play a vital role in providing portable protection against ballistic threats. At AAC Polymer Technologies, we specialize in crafting advanced ballistic shields designed to offer maximum safety and performance for various critical applications.

What are Ballistic Shields?

Ballistic shields are portable protective devices made from high-strength materials such as aramid fibers, ultra-high-molecular-weight polyethylene (UHMWPE), and advanced ceramics. These shields are designed to stop or deflect bullets and shrapnel, providing a mobile barrier that enhances the safety of personnel in high-risk situations.

Protection Levels of Ballistic Shields

Ballistic shields are rated based on their ability to withstand different types of ammunition, according to standards like the National Institute of Justice (NIJ). Here are the common protection levels:

- NIJ Level III-A: Provides protection against high-velocity handgun rounds, including .44 Magnum and .357 SIG. Ideal for law enforcement and personal security use.

- NIJ Level III: Offers protection against rifle rounds such as 7.62mm NATO FMJ and .308 Winchester. Suitable for tactical operations where rifle threats are present.

- NIJ Level IV: The highest level of protection, capable of stopping armor-piercing rifle rounds such as .30-06 AP. Essential for military and high-risk law enforcement operations.

Applications of Ballistic Shields

- Law Enforcement:

- Tactical Operations: Ballistic shields are used by SWAT teams and tactical units during high-risk operations, providing portable cover and protection against gunfire.

- Hostage Rescue: During hostage rescue missions, ballistic shields offer crucial protection for both officers and civilians.

- Military:

- Combat Missions: In military operations, ballistic shields provide soldiers with a mobile defense against small arms fire and shrapnel.

- Checkpoint Security: Used at checkpoints and during patrols, these shields enhance the safety of personnel in conflict zones.

- Personal Protection:

- VIP Security: Ballistic shields are used by bodyguards and security personnel to protect VIPs and dignitaries during public appearances and high-risk travel.

- Civilian Use: In certain scenarios, civilians in high-risk areas may use ballistic shields for added protection.

Product Range at AAC Polymer Technologies

At AAC Polymer Technologies, we offer a diverse range of ballistic shields tailored to meet various protection needs:

- Standard Shields: Designed for general use, providing reliable protection in a lightweight and easy-to-handle format.

- Advanced Ceramic Shields: Made from advanced ceramics such as alumina and silicon carbide, these shields offer superior protection against high-velocity rounds and armor-piercing bullets.

- Transparent Ballistic Shields: Combining visibility with protection, these shields are ideal for situations where situational awareness is critical.

- Custom Solutions: Tailored shields designed to meet specific requirements, including size, shape, and protection level, for specialized applications.

Why Choose AAC Polymer Technologies?

AAC Polymer Technologies is committed to delivering top-tier ballistic protection solutions. Our ballistic shields undergo rigorous testing to meet and exceed international standards, ensuring maximum reliability and performance. With our expertise in advanced materials and innovative design, we provide products that offer unparalleled protection in the most demanding environments.

In the realm of ballistic protection, hard ballistic plates stand as the ultimate defense against high-caliber and armor-piercing threats. At AAC Polymer Technologies, we push the boundaries of safety and durability with our cutting-edge hard ballistic plates, tailored for a variety of critical applications.

What are Hard Ballistic Plates?

Hard ballistic plates, also known as hard armor plates, are rigid protective panels crafted from advanced materials such as ceramic (alumina, silicon carbide, boron carbide) or ultra-high-molecular-weight polyethylene (UHMWPE). These plates are engineered to halt high-velocity projectiles and armor-piercing rounds, providing a level of protection that soft ballistic panels cannot match.

Protection Levels of Hard Ballistic Plates

Hard ballistic plates are rated based on their ability to stop various types of ammunition, following standards like those set by the National Institute of Justice (NIJ). Here’s a breakdown of the common protection levels:

- NIJ Level III: Designed to stop rifle rounds like the 7.62mm NATO full metal jacket (FMJ) and .308 Winchester. Ideal for tactical vests used by military and law enforcement.

- NIJ Level IV: The pinnacle of ballistic protection, capable of halting armor-piercing rifle rounds such as the .30-06 AP. Essential for operations in high-risk environments.

Applications of Hard Ballistic Plates

- Personal Protective Equipment (PPE):

- Body Armor: Hard ballistic plates fit into plate carriers and tactical vests, providing frontline personnel with critical protection against high-velocity and armor-piercing rounds.

- Military Gear: These plates are a standard for soldiers worldwide, ensuring maximum protection during combat operations.

- Vehicle Armor:

- Military Vehicles: Integrated into the armor of military vehicles, hard ballistic plates protect against large caliber projectiles and explosive devices.

- Civilian Armored Vehicles: Used in armored cars and SUVs for VIP protection, these plates offer high-level security in dangerous environments.

- Structural Reinforcement:

- Buildings and Infrastructure: Hard ballistic plates enhance the protection of critical infrastructure and buildings against ballistic threats and explosive impacts.

Product Range at AAC Polymer Technologies

At AAC Polymer Technologies, we offer a wide array of hard ballistic plates to meet various protection needs:

- Ceramic Plates: Crafted from advanced ceramics like alumina, silicon carbide, and boron carbide, these plates deliver outstanding protection against high-velocity and armor-piercing rounds.

- Polyethylene Plates: Lightweight yet highly protective, these plates offer enhanced mobility without sacrificing safety, perfect for prolonged operations.

- Multi-Curve Plates: Ergonomically designed to conform to the body, providing improved comfort and mobility.

- Custom Solutions: Tailored to specific requirements, including size, shape, and protection level, for specialized applications.

Why Choose AAC Polymer Technologies?

At AAC Polymer Technologies, we are committed to delivering top-tier ballistic protection solutions. Our hard ballistic plates undergo rigorous testing to meet and exceed international standards, ensuring maximum reliability and performance. With our expertise in advanced materials and innovative design, we provide products that offer unmatched protection in the most demanding environments.

Conclusion

Hard ballistic plates represent the zenith of protective technology, offering unrivaled defense against extreme threats. At AAC Polymer Technologies, we pride ourselves on providing the highest quality hard ballistic plates to safeguard lives in diverse and high-risk scenarios. For more information on our products and how they can meet your protection needs, contact us today.

Soft Ballistic Panels: Advanced Protection for Dynamic Threats

In an ever-changing world, ensuring personal safety against ballistic threats is crucial. Soft ballistic panels provide a versatile and effective solution for various applications, from personal protective equipment to vehicle and structural reinforcement. At AAC Polymer Technologies, we offer a comprehensive range of soft ballistic panels designed to meet diverse protection needs.

What are Soft Ballistic Panels?

Soft ballistic panels are flexible, lightweight layers of materials such as aramid fibers (like Kevlar®) or ultra-high-molecular-weight polyethylene (UHMWPE). These panels are engineered to absorb and disperse the energy from ballistic impacts, providing protection without compromising mobility and comfort.

Protection Levels of Soft Ballistic Panels

Soft ballistic panels are rated based on their ability to stop different types of ammunition, as per standards such as the National Institute of Justice (NIJ) in the United States. Here are the common protection levels:

- NIJ Level II-A: Provides protection against lower-velocity handgun rounds such as 9mm and .40 S&W. These panels are very lightweight and flexible, making them ideal for everyday wear.

- NIJ Level II: Offers increased protection against higher-velocity 9mm rounds and .357 Magnum rounds. These panels strike a balance between protection and comfort.

- NIJ Level III-A: Protects against high-velocity handgun rounds, including .44 Magnum and .357 SIG. This level is commonly used in soft body armor for law enforcement and personal protection.

- NIJ Level III and IV: These levels are typically associated with hard ballistic plates, but some advanced soft armor solutions can offer protection against rifle rounds when used in conjunction with hard plates.

Applications of Soft Ballistic Panels

- Personal Protective Equipment (PPE):

- Body Armor: Soft ballistic panels are used in bulletproof vests, providing a high degree of protection while allowing for flexibility and ease of movement. They are popular among law enforcement, military personnel, and private security.

- Protective Clothing: Integrated into clothing, soft ballistic panels can provide discreet protection for VIPs and civilians in high-risk areas.

- Vehicle Armor:

- Cars and SUVs: Soft ballistic panels can be installed in civilian and military vehicles to offer protection against handgun threats without significantly adding to the vehicle’s weight.

- Aircraft: In aviation, these panels help in creating lightweight armor solutions for both military and civilian aircraft.

- Structural Reinforcement:

- Buildings and Infrastructure: Soft ballistic panels can be installed in walls, doors, and windows to protect against ballistic threats, offering additional security in sensitive or high-risk locations.

Product Range at AAC Polymer Technologies

At AAC Polymer Technologies, we offer a diverse range of soft ballistic panels tailored to various needs:

- Standard Panels: Designed for general use, providing reliable protection in everyday scenarios.

- High-Flexibility Panels: Offering enhanced flexibility for applications where mobility and comfort are paramount.

- Ultra-Lightweight Panels: Combining advanced materials to provide maximum protection with minimal weight, ideal for extended wear.

- Custom Solutions: Tailored panels designed to meet specific requirements, including size, shape, and protection level, for specialized applications.

Why Choose AAC Polymer Technologies?

AAC Polymer Technologies is committed to delivering top-tier ballistic protection solutions. Our soft ballistic panels are rigorously tested to meet international standards, ensuring maximum safety and performance. With our expertise in advanced materials and innovative design, we provide products that offer unparalleled protection and comfort.

Conclusion

Soft ballistic panels represent a critical component in modern protective solutions, offering flexibility, lightweight protection, and adaptability to various threats. At AAC Polymer Technologies, we are dedicated to providing the highest quality ballistic protection to safeguard lives in diverse environments. For more information on our products and how they can meet your protection needs, contact us today.

In the world of defense and security, the materials chosen for protective gear and armor are vital for ensuring the highest levels of safety and performance. At AAC Polymer Technologies, we integrate advanced materials like alumina into our ballistic protection solutions to provide superior strength and reliability.

What is Alumina?

Alumina, also known as aluminum oxide (Al2O3), is a ceramic material widely recognized for its hardness, high melting point, and excellent thermal and electrical insulation properties. These characteristics make it an ideal choice for various demanding applications, including ballistic protection.

Properties of Alumina

- High Hardness: Alumina is extremely hard, providing excellent resistance to wear and abrasion.

- Thermal Stability: It has a high melting point and can maintain its properties at elevated temperatures, making it suitable for high-temperature environments.

- Chemical Resistance: Alumina is resistant to most acids and alkalis, enhancing its durability in harsh conditions.

- Electrical Insulation: It is an excellent electrical insulator, useful in applications requiring non-conductive materials.

- High Compressive Strength: Alumina has high compressive strength, making it ideal for applications subjected to heavy loads and impacts.

Applications of Alumina in Ballistic Protection

- Personal Protective Equipment (PPE):

- Body Armor: Alumina is used in the manufacture of bulletproof vests and helmets, providing superior protection against ballistic threats while maintaining a manageable weight.

- Protective Inserts: It is also utilized in armor inserts, enhancing the overall ballistic resistance of personal protective gear.

- Vehicle Armor:

- Military Vehicles: Alumina ceramics are used in the armor plating of military vehicles, offering enhanced protection against ballistic threats without compromising mobility.

- Aircraft: In aviation, alumina is used in lightweight armor solutions, contributing to both safety and fuel efficiency.

- Industrial Applications:

- Abrasive Materials: Due to its hardness, alumina is used in abrasive applications such as grinding, cutting, and sandblasting.

- High-Temperature Applications: Its thermal stability makes it suitable for use in furnaces, kilns, and other high-temperature environments.

- Structural Reinforcement:

- Buildings and Infrastructure: Alumina is used to reinforce critical infrastructure, providing protection against blast impacts and improving overall structural integrity.

Why Choose AAC Polymer Technologies?

At AAC Polymer Technologies, we leverage the advanced properties of alumina to develop state-of-the-art ballistic protection solutions. Our commitment to innovation and quality ensures that our products meet the highest standards of safety and performance. Whether it’s personal protective equipment or vehicle armor, our expertise in alumina-based technologies guarantees reliability in the most demanding environments.

Conclusion

Alumina represents a significant advancement in material science, offering unparalleled protection and performance in a variety of applications. At AAC Polymer Technologies, we are proud to utilize the potential of alumina to safeguard lives and enhance the capabilities of defense systems. For more information on our products and how alumina can benefit your needs, contact us today.

Aramid: The Backbone of Modern Ballistic Protection

In the ever-evolving landscape of defense and security, the materials used in the construction of protective gear and armor play a crucial role. One such material, known for its exceptional strength and durability, is aramid. At AAC Polymer Technologies, we specialize in integrating advanced materials like aramid into our ballistic protection solutions to ensure the highest level of safety and performance.

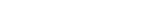

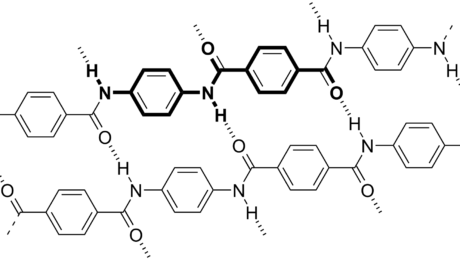

What is Aramid?

Aramid, short for aromatic polyamide, is a class of heat-resistant and strong synthetic fibers. These fibers are characterized by their exceptional strength-to-weight ratio, thermal stability, and resistance to impact and abrasion. The most well-known aramid fibers include Kevlar®, Twaron®, and Nomex®, which have become synonymous with high-performance applications.

Properties of Aramid

- High Strength and Durability: Aramid fibers exhibit remarkable tensile strength, making them ideal for applications where durability and resistance to mechanical stress are paramount.

- Thermal Resistance: Aramid maintains its integrity and performance at high temperatures, making it suitable for use in environments exposed to extreme heat.

- Lightweight: Despite its strength, aramid is lightweight, which is a crucial factor in the design of personal protective equipment (PPE) and vehicle armor.

- Chemical Resistance: Aramid fibers are resistant to many chemicals and solvents, enhancing their longevity and reliability in harsh conditions.

- Flexibility: The fibers are flexible, allowing for versatility in design and application, from soft body armor to rigid composite panels.

Applications of Aramid in Ballistic Protection

- Personal Protective Equipment (PPE):

- Body Armor: Aramid is a key component in the manufacture of bulletproof vests and helmets. Its ability to absorb and disperse energy from high-impact projectiles makes it essential for personal protection.

- Gloves and Clothing: Heat-resistant aramid fibers are used in gloves and clothing for military and first responders, offering protection against fire and heat.

- Vehicle Armor:

- Military Vehicles: Aramid composites are used in the armor of military vehicles to provide enhanced protection against ballistic threats while maintaining mobility due to their lightweight nature.

- Aircraft: In aviation, aramid-reinforced composites help in creating lightweight yet durable components, contributing to both safety and fuel efficiency.

- Structural Reinforcement:

- Buildings and Infrastructure: Aramid fibers are used to reinforce buildings and critical infrastructure, providing protection against blast impacts and improving overall structural integrity.

- Sporting Goods and Equipment:

- Sports and Recreation: Beyond defense applications, aramid fibers are used in the manufacturing of high-performance sporting goods, including protective gear for extreme sports, due to their strength and durability.

Why Choose AAC Polymer Technologies?

At AAC Polymer Technologies, we leverage the advanced properties of aramid fibers to develop state-of-the-art ballistic protection solutions. Our commitment to innovation and quality ensures that our products meet the highest standards of safety and performance. Whether it’s personal protective equipment or vehicle armor, our expertise in aramid-based technologies guarantees reliability in the most demanding environments.

Conclusion

Aramid fibers represent a pinnacle of material science, offering unparalleled protection and performance in a variety of applications. At AAC Polymer Technologies, we are proud to harness the potential of aramid to safeguard lives and enhance the capabilities of defense systems. For more information on our products and how aramid can benefit your needs, contact us today.

In the defense industry and ballistic protection technologies, the materials used play a crucial role in ensuring safety and performance. At AAC Polymer Technologies, we integrate advanced materials like polyethylene into our ballistic protection solutions to provide superior durability and performance.

What is Polyethylene?

Polyethylene is a thermoplastic polymer with variations such as high-density polyethylene (HDPE) and ultra-high-molecular-weight polyethylene (UHMWPE). UHMWPE, in particular, stands out in ballistic protection applications due to its exceptional strength, low weight, and superior wear resistance. The long molecular chains in UHMWPE give it unique properties that make it ideal for demanding environments.

Properties of Polyethylene

- High Strength-to-Weight Ratio: UHMWPE fibers are incredibly strong while remaining lightweight, making them perfect for use in personal protective equipment and vehicle armor.

- Abrasion Resistance: Polyethylene’s resistance to wear and tear ensures longevity and reliability, even in harsh conditions.

- Chemical Resistance: It is resistant to many chemicals, oils, and solvents, enhancing its durability.

- Impact Resistance: Polyethylene can absorb and dissipate energy from high-impact forces, making it essential for ballistic protection.

- Low Friction: The low coefficient of friction of UHMWPE contributes to its versatility in various applications.

Applications of Polyethylene in Ballistic Protection

- Personal Protective Equipment (PPE):

- Body Armor: UHMWPE is a key material in the manufacture of bulletproof vests and helmets. Its ability to stop bullets and shrapnel while being lightweight makes it indispensable for personal protection.

- Protective Clothing: Polyethylene fibers are used in protective clothing for military and law enforcement personnel, offering resistance to cuts and abrasions.

- Vehicle Armor:

- Military Vehicles: Polyethylene composites are used in military vehicle armor, providing enhanced protection against ballistic threats while maintaining vehicle maneuverability due to their lightweight nature.

- Aircraft: In aviation, UHMWPE-reinforced composites help create lightweight, durable components, improving both safety and fuel efficiency.

- Structural Reinforcement:

- Buildings and Infrastructure: Polyethylene fibers reinforce buildings and critical infrastructure, providing protection against blast impacts and improving overall structural integrity.

- Medical and Sporting Equipment:

- Orthopedic Implants: UHMWPE is used in medical applications, such as joint replacements, due to its biocompatibility and wear resistance.

- Sports Gear: Beyond defense applications, polyethylene is used in high-performance sports gear, offering protection and durability for extreme sports enthusiasts.

Why Choose AAC Polymer Technologies?

At AAC Polymer Technologies, we harness the advanced properties of polyethylene to develop state-of-the-art ballistic protection solutions. Our commitment to innovation and quality ensures that our products meet the highest standards of safety and performance. Whether it’s personal protective equipment or vehicle armor, our expertise in polyethylene-based technologies guarantees reliability in the most demanding environments.

Conclusion

Polyethylene, particularly UHMWPE, represents a significant advancement in material science, offering unparalleled protection and performance in a variety of applications. At AAC Polymer Technologies, we are proud to utilize the potential of polyethylene to safeguard lives and enhance the capabilities of defense systems. For more information on our products and how polyethylene can benefit your needs, contact us today.

In the realm of advanced materials for defense and security, few substances match the extraordinary properties of boron carbide. At AAC Polymer Technologies, we leverage this cutting-edge material to create superior ballistic protection solutions that ensure maximum safety and performance.

What is Boron Carbide?

Boron carbide (B4C) is a ceramic material that ranks among the hardest materials known, just behind diamond and cubic boron nitride. It is renowned for its exceptional hardness, low density, and high chemical stability, making it a preferred choice for demanding applications in ballistic protection.

Properties of Boron Carbide

- Extreme Hardness: Boron carbide’s exceptional hardness provides outstanding resistance to wear and abrasion, making it ideal for use in protective armor.

- Lightweight: Despite its hardness, boron carbide is remarkably lightweight, which is crucial for applications where mobility and ease of use are essential.

- High Chemical Stability: This material is highly resistant to chemical attacks, enhancing its durability in harsh environments.

- Thermal Stability: Boron carbide maintains its properties at high temperatures, making it suitable for use in extreme conditions.

- Impact Resistance: Its ability to absorb and dissipate energy from high-impact forces makes boron carbide an excellent choice for ballistic protection.

Applications of Boron Carbide in Ballistic Protection

- Personal Protective Equipment (PPE):

- Body Armor: Boron carbide is used in the manufacture of bulletproof vests and helmets, providing superior protection against high-velocity projectiles while keeping the weight manageable.

- Protective Inserts: It is also used in protective inserts for body armor, enhancing the overall ballistic resistance.

- Vehicle Armor:

- Military Vehicles: Boron carbide ceramics are used in the armor plating of military vehicles, offering enhanced protection against ballistic threats without compromising on maneuverability.

- Aircraft: In aviation, boron carbide is used in lightweight armor solutions, contributing to both safety and fuel efficiency.

- Industrial Applications:

- Abrasive Materials: Due to its hardness, boron carbide is used in abrasive applications such as grinding, lapping, and cutting tools.

- Nuclear Industry: It is used in control rods and neutron shielding due to its ability to absorb neutrons.

- Structural Reinforcement:

- Buildings and Infrastructure: Boron carbide is used to reinforce critical infrastructure, providing protection against blast impacts and improving overall structural integrity.

Why Choose AAC Polymer Technologies?

At AAC Polymer Technologies, we harness the advanced properties of boron carbide to develop state-of-the-art ballistic protection solutions. Our commitment to innovation and quality ensures that our products meet the highest standards of safety and performance. Whether it’s personal protective equipment or vehicle armor, our expertise in boron carbide-based technologies guarantees reliability in the most demanding environments.

Conclusion

Boron carbide represents a pinnacle in material science, offering unparalleled protection and performance in a variety of applications. At AAC Polymer Technologies, we are proud to utilize the potential of boron carbide to safeguard lives and enhance the capabilities of defense systems. For more information on our products and how boron carbide can benefit your needs, contact us today.

In the defense and security industries, the materials used in protective gear and armor are critical to ensuring safety and effectiveness. At AAC Polymer Technologies, we incorporate advanced materials like silicon carbide into our ballistic protection solutions to offer superior performance and durability.

What is Silicon Carbide?

Silicon carbide (SiC) is a ceramic material known for its exceptional hardness, high thermal conductivity, and low thermal expansion. These properties make it an excellent choice for applications requiring high-performance materials that can withstand extreme conditions.

Properties of Silicon Carbide

- Exceptional Hardness: Silicon carbide is one of the hardest known materials, providing excellent resistance to wear and abrasion.

- High Thermal Conductivity: It efficiently dissipates heat, making it suitable for high-temperature applications.

- Low Thermal Expansion: This property ensures that silicon carbide retains its structural integrity under thermal stress.

- Lightweight: Despite its hardness, silicon carbide is relatively lightweight, which is advantageous for applications requiring mobility.

- Chemical Resistance: It is resistant to most chemicals, adding to its durability and longevity.

Applications of Silicon Carbide in Ballistic Protection

- Personal Protective Equipment (PPE):

- Body Armor: Silicon carbide is used in the manufacture of bulletproof vests and helmets, providing superior protection against high-velocity projectiles while remaining lightweight.

- Protective Inserts: It is also used in armor inserts, enhancing the overall ballistic resistance of protective gear.

- Vehicle Armor:

- Military Vehicles: Silicon carbide ceramics are used in the armor plating of military vehicles, offering enhanced protection against ballistic threats without compromising on maneuverability.

- Aircraft: In aviation, silicon carbide is used in lightweight armor solutions, contributing to both safety and fuel efficiency.

- Industrial Applications:

- Abrasive Materials: Due to its hardness, silicon carbide is used in abrasive applications such as grinding, cutting, and lapping tools.

- High-Temperature Applications: Its thermal properties make it suitable for use in furnaces, kilns, and other high-temperature environments.

- Structural Reinforcement:

- Buildings and Infrastructure: Silicon carbide is used to reinforce critical infrastructure, providing protection against blast impacts and improving overall structural integrity.

Why Choose AAC Polymer Technologies?

At AAC Polymer Technologies, we leverage the advanced properties of silicon carbide to develop state-of-the-art ballistic protection solutions. Our commitment to innovation and quality ensures that our products meet the highest standards of safety and performance. Whether it’s personal protective equipment or vehicle armor, our expertise in silicon carbide-based technologies guarantees reliability in the most demanding environments.

Conclusion

Silicon carbide represents a significant advancement in material science, offering unparalleled protection and performance in a variety of applications. At AAC Polymer Technologies, we are proud to utilize the potential of silicon carbide to safeguard lives and enhance the capabilities of defense systems. For more information on our products and how silicon carbide can benefit your needs, contact us today.