In the world of defense and security, the materials chosen for protective gear and armor are vital for ensuring the highest levels of safety and performance. At AAC Polymer Technologies, we integrate advanced materials like alumina into our ballistic protection solutions to provide superior strength and reliability.

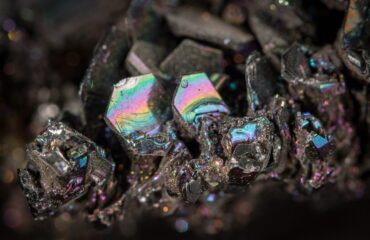

What is Alumina?

Alumina, also known as aluminum oxide (Al2O3), is a ceramic material widely recognized for its hardness, high melting point, and excellent thermal and electrical insulation properties. These characteristics make it an ideal choice for various demanding applications, including ballistic protection.

Properties of Alumina

- High Hardness: Alumina is extremely hard, providing excellent resistance to wear and abrasion.

- Thermal Stability: It has a high melting point and can maintain its properties at elevated temperatures, making it suitable for high-temperature environments.

- Chemical Resistance: Alumina is resistant to most acids and alkalis, enhancing its durability in harsh conditions.

- Electrical Insulation: It is an excellent electrical insulator, useful in applications requiring non-conductive materials.

- High Compressive Strength: Alumina has high compressive strength, making it ideal for applications subjected to heavy loads and impacts.

Applications of Alumina in Ballistic Protection

- Personal Protective Equipment (PPE):

- Body Armor: Alumina is used in the manufacture of bulletproof vests and helmets, providing superior protection against ballistic threats while maintaining a manageable weight.

- Protective Inserts: It is also utilized in armor inserts, enhancing the overall ballistic resistance of personal protective gear.

- Vehicle Armor:

- Military Vehicles: Alumina ceramics are used in the armor plating of military vehicles, offering enhanced protection against ballistic threats without compromising mobility.

- Aircraft: In aviation, alumina is used in lightweight armor solutions, contributing to both safety and fuel efficiency.

- Industrial Applications:

- Abrasive Materials: Due to its hardness, alumina is used in abrasive applications such as grinding, cutting, and sandblasting.

- High-Temperature Applications: Its thermal stability makes it suitable for use in furnaces, kilns, and other high-temperature environments.

- Structural Reinforcement:

- Buildings and Infrastructure: Alumina is used to reinforce critical infrastructure, providing protection against blast impacts and improving overall structural integrity.

Why Choose AAC Polymer Technologies?

At AAC Polymer Technologies, we leverage the advanced properties of alumina to develop state-of-the-art ballistic protection solutions. Our commitment to innovation and quality ensures that our products meet the highest standards of safety and performance. Whether it’s personal protective equipment or vehicle armor, our expertise in alumina-based technologies guarantees reliability in the most demanding environments.

Conclusion

Alumina represents a significant advancement in material science, offering unparalleled protection and performance in a variety of applications. At AAC Polymer Technologies, we are proud to utilize the potential of alumina to safeguard lives and enhance the capabilities of defense systems. For more information on our products and how alumina can benefit your needs, contact us today.